The WHN 13/15 plate-type horizontal boring machine is an advanced piece of industrial engineering designed to perform some of the most demanding CNC machining tasks in heavy industries. Built for reliability, flexibility, and precision, this machine stands out when it comes to processing large, heavy, and complex workpieces that require uncompromising accuracy and surface quality.

Horizontal boring machines are essential tools in the world of metalworking, heavy equipment manufacturing, and precision engineering. With the WHN 13/15, manufacturers gain access to a system that is not only robust in construction but also enhanced by modern CNC control systems that maximize productivity while minimizing human error. This machine represents a perfect balance between traditional mechanical stability and modern digital intelligence.Understanding the WHN 13/15 Plate-Type Boring Machine

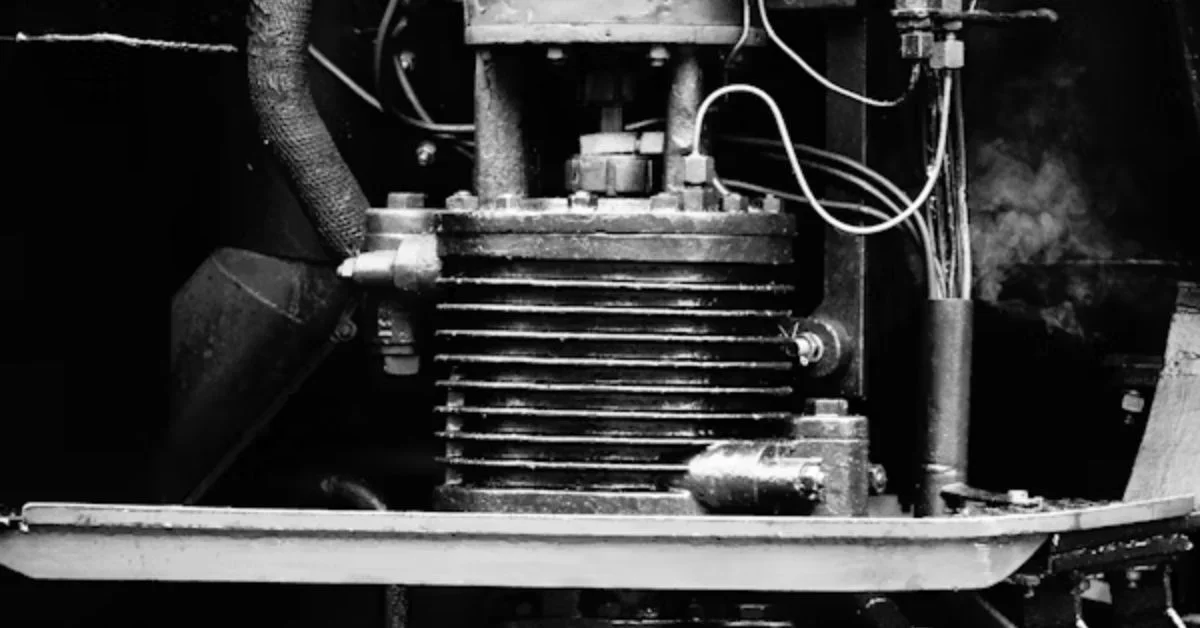

The “plate-type” designation refers to the heavy-duty bed and plate construction that forms the base of this machine. This design provides a stable, rigid platform for machining operations, ensuring that vibrations are minimized, even when handling oversized workpieces.

The WHN 13/15 is built for horizontal boring operations, meaning the spindle is mounted horizontally, allowing it to machine the sides of large objects. This makes it ideal for tasks such as boring, milling, drilling, and threading in industries like energy, aerospace, shipbuilding, mining, and large-scale automotive.

Key Features of the WHN 13/15

- Spindle Flexibility:

Equipped with a high-torque spindle capable of machining both hard and soft materials. - Large Work Area:

Built to handle massive components with wide plate dimensions and extended travel ranges. - CNC Control:

Advanced CNC systems ensure precision, repeatability, and integration into digital workflows. - Heavy Load Capacity:

Designed to bear extreme weights, the WHN 13/15 excels at machining bulky industrial parts. - Versatility:

Performs boring, drilling, contour milling, facing, and even threading operations on large parts.

Technical Specifications Overview

While variations exist depending on configuration, the WHN 13/15 typically provides the following specifications:

| Specification | WHN 13/15 Capability |

|---|---|

| Spindle Diameter | 130 mm to 150 mm |

| Spindle Power Output | High-torque motor for heavy cutting |

| X-Axis Travel | Up to 5000 mm or more |

| Y-Axis Travel | Around 2500 mm |

| Z-Axis Travel | Approximately 1500–2000 mm |

| W-Axis (Spindle Travel) | 700–900 mm |

| Table Load Capacity | 20–40 tons (depending on model) |

| CNC System Integration | Fully programmable with digital controls |

| Precision Tolerance | Micron-level repeatability |

These specifications demonstrate why the WHN 13/15 is a preferred solution for machining extremely heavy and complex components.

Applications of WHN 13/15

The WHN 13/15 machine finds its application across multiple industries that require large-scale precision machining.

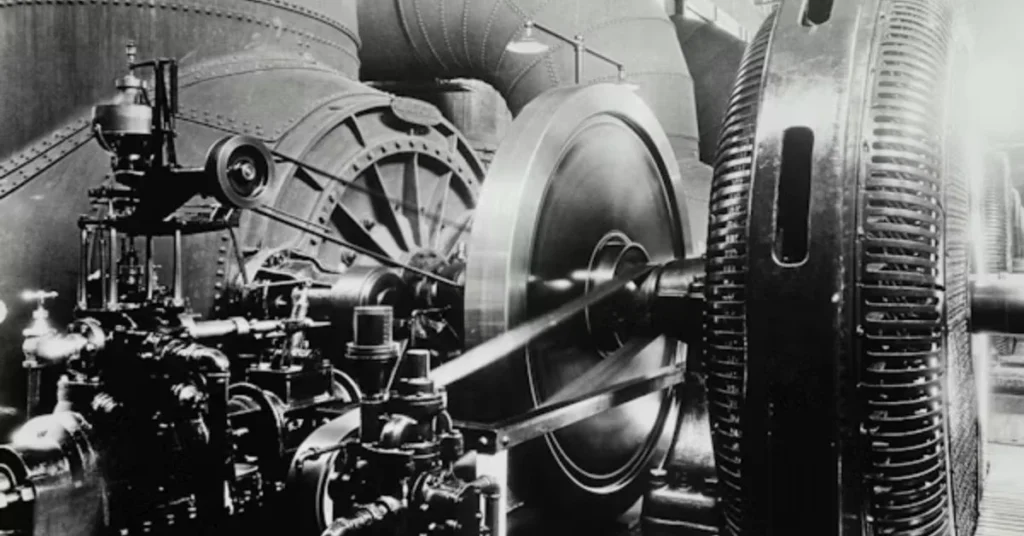

1. Energy Industry

Used to manufacture turbines, generators, and energy plant components that demand precise boring and milling on massive parts.

2. Aerospace

Machining of aircraft structural components, landing gear, and aerospace housings where accuracy is critical.

3. Shipbuilding

Large-scale machining of engine blocks, shafts, and structural elements of ships and submarines.

4. Mining and Heavy Equipment

Production of excavator arms, drilling rigs, and crushers—all requiring extreme durability and heavy-duty machining.

5. Automotive and Rail

Used for large diesel engines, transmission housings, and railway equipment parts.

CNC Machining Advantages in WHN 13/15

The integration of CNC (Computer Numerical Control) technology is what makes the WHN 13/15 machine truly modern. Unlike traditional horizontal boring mills, this system provides:

- High Repeatability: CNC ensures the same part can be produced consistently without deviations.

- Complex Geometries: CNC programming allows intricate shapes, curves, and contours to be machined.

- Reduced Human Error: Automation minimizes the risk of inaccuracies caused by manual operations.

- Faster Cycle Times: Digital optimization improves efficiency and productivity.

- Smart Manufacturing: Integration with CAD/CAM systems supports Industry 4.0 workflows.

Comparative Analysis: WHN 13 vs WHN 15

The WHN 13 and WHN 15 models are part of the same family but differ in spindle size and work capacity.

| Feature | WHN 13 | WHN 15 |

|---|---|---|

| Spindle Diameter | 130 mm | 150 mm |

| Max Workpiece Size | Large | Extra-large |

| Load Capacity | ~20 tons | ~40 tons |

| Application Focus | General heavy machining | Ultra-heavy machining |

This comparison shows that the WHN 15 is an expanded version of the WHN 13, suitable for even larger and heavier parts.

Benefits of Using WHN 13/15 in Industry

- Unmatched Stability: Plate-type construction ensures reduced vibration.

- Enhanced Productivity: CNC integration speeds up complex machining tasks.

- Versatility: Handles multiple machining operations in a single setup.

- Scalability: Suitable for small-batch or large-scale industrial production.

- Longevity: Built with robust materials, ensuring decades of reliable service.

Challenges and Considerations

While powerful, using the WHN 13/15 requires careful planning:

- Space Requirements: The machine is large and demands significant floor space.

- Skilled Operation: Requires CNC-trained operators and programmers.

- Investment Costs: Acquisition and maintenance are costly but justified by productivity.

- Energy Consumption: Heavy-duty motors consume high levels of power.

Future of Machines Like WHN 13/15

The WHN 13/15 reflects the future of heavy CNC machining, where machines will become increasingly:

- Digitally Connected: With IoT-enabled monitoring and predictive maintenance.

- Energy Efficient: Optimized motors and hybrid systems to reduce consumption.

- Autonomous: Incorporating AI for adaptive machining and real-time error correction.

These advancements will make machines like WHN 13/15 even more critical for the industries of tomorrow.

Conclusion

The WHN 13/15 plate-type horizontal boring machine is a true workhorse in the world of CNC heavy machining. With its combination of powerful spindle capacity, rigid construction, and advanced CNC integration, it enables industries to handle the most challenging machining tasks with precision and efficiency. From energy to aerospace, mining to shipbuilding, the WHN 13/15 ensures that manufacturers can meet modern demands for large-scale, accurate, and reliable component production.

FAQs

Q1: What makes the WHN 13/15 unique compared to other boring machines?

This combines plate-type stability with CNC control, offering unmatched accuracy and load-handling capacity for large components.

Q2: Can this machine both hard and soft materials?

Yes, its high-torque spindle allows machining of both extremely hard metals and softer alloys with equal precision.

Q3: Which industries use the WHN the most?

It is widely used in aerospace, shipbuilding, mining, energy, and heavy equipment manufacturing due to its ability to handle oversized parts.

Q4: What is the main difference between WHN and WHN 15?

The WHN 15 has a larger spindle diameter and greater load capacity, making it suitable for even heavier and larger workpieces.

Q5: How does CNC integration improve WHN performance?

CNC integration ensures precision, repeatability, and efficiency while enabling the machining of complex shapes that manual operations cannot achieve.

For more information, click here.